The Essential Guide To Gear Oil What It Is And Why It's Important

As a product in various types of mechanisms, oil for gears ensures long-term and smooth operation of anything. Gearbox lubricant as well as differential lubricant and gear oil is known to lower friction and wear on gears, along with preventing corrosion. There are a variety of gear oils that can be accessed. They are all developed to serve individual purposes and applications. Oils have different viscosities, additives, and composition that allow them to use particular functions. Gear oils can be classified into three, which are mineral oil, synthetic oil, and semi-synthetic oil. These have separate advantages for each, knowing the difference is important for identifying the right type to use for your equipment. By using the right gear oil, you can realize better performance, minimize the maintenance costs, and also increase the lifespan of your machine or vehicle.

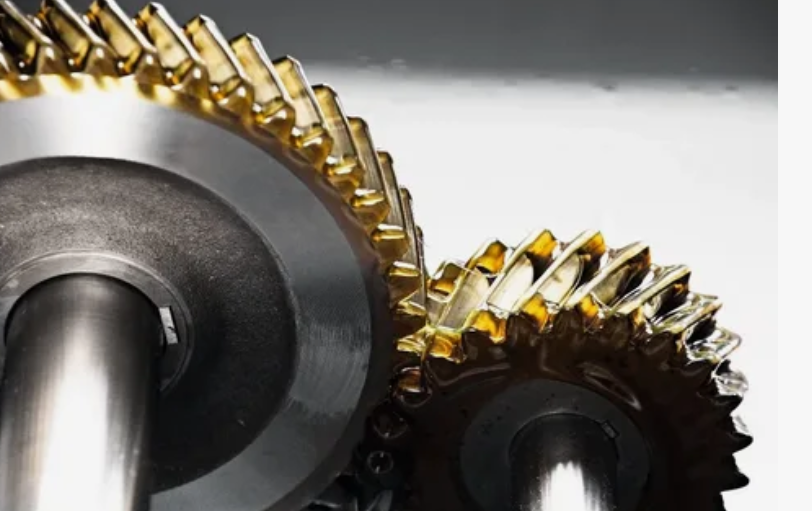

What is Gear Oil Used For?

The gear oil is used for gear oil function is depend on types of gearbox oil and primary role in lubrication in mechanical systems with gears. These effects gear oil properties comprise prevention of friction that later causes exclusion of metal contacts between parts moving in those systems. Long-term contacts may damage the parts because of wear. Automotive and industrial applications have the use of gear lubricant in transmissions, differentials, gearboxes, and transfer cases. Gear oil uses in automotive systems help prevent excessive heat generation while allowing for smooth meshing of gears by maintaining the efficiency and a long life of the transmission. Gear oil is relied upon in equipment that includes machinery used in manufacturing as well as other heavy equipment to keep their parts working. Due to its protective film formation over gear surfaces, gear oil minimizes friction, reduces wear, and ensures optimal performance, hence making it an indispensable component in mechanical systems.

There are Different Types of Gear Oil

How many types of gear oil – Gear oil types come in various types that have been designed to fit specific applications and requirements. The most commonly used gearbox oil types are mineral, synthetic, and semi-synthetic gear oils. Mineral gear oils can be derived from crude oil and may be safe for applications having relatively stabilized temperatures. Synthetic gear oils chemically engineer superior lubrication, stability, and protection under extreme temperatures and pressures. They often gear oil types and uses in high-performance vehicles or heavy-duty industrial machinery. Semi-synthetic gear oils combine the properties of both mineral and synthetic oils, hence providing a balance between them: cost-effectiveness and performance-enhancing features. There are also other gear oils that have special additives, like EP, which offer enhanced protection when exposed to pressure in high load conditions. The right type to choose would depend on the needs of your equipment, operating conditions, and those recommended by the manufacturer.

Functions and Applications of Gear Oil

Gear oil composition for It multi-functions, as it can reduce friction wear, heat dispensation, and prevent corrosion. In use, it is majorly applied in automotive application by the use of gear oil within the transmission, differential, and transfer case for friction-free operation. It has high viscosity, enabling it to stick well onto gear surfaces to ensure uniform lubrication, even when exposed to extreme levels of pressure. It is used in industrial gear lubricants sectors to lubricate the machinery, conveyor systems, and heavy equipment. It reduces friction and enhances the overall efficiency as well as the life of the gears in it. It serves as a kind of protective coating between two metallic surfaces without which pitting, scuffing, or corrosion might occur. It also helps reduce noise as well as some sort of vibration dampening. So, overall, its efficiency increased mechanical systems. The right gear oil provides optimal performance, reduces downtime, and minimizes the cost of maintenance.

Gear Oil Grades and Numbers

Gear oil grades and numbers provide information on viscosity and performance features. By examining viscosity levels in terms of various temperatures, SAE established a grading system to classify gear oil purpose. Gear oil classification most common grades include SAE 75W-90, 80W-90, and 85W-140, where the numbers denote the oil’s viscosity at low and high temperatures. For instance, 75W-90 gear oil will continue to be fluid at cold temperatures (75W) but maintain protective properties at high temperatures (90). Those grades determine which oils are most suitable for which applications and guarantee optimal lubrication and protection under different operation conditions. Thicker oils provide extra protections in heavy-duty operations, while thinner oils are the best option for light-duty vehicles or in cold climates. Knowing such grades helps you make a correct choice of gear oil for your equipment.

Synthetic versus Conventional Gear Oil

Synthetic and conventional gear oils have different compositions and performance, as well as cost. Conventional gear oil that came out from the refining process of crude oil is available for standard applications where temperature and pressure were relatively stable. It provides sufficient lubrication and protection in typical driving or operation conditions. Synthetic gear oil is chemically engineered to offer superior performance, especially in extreme temperatures and high-load situations. It has better oxidation resistance, thermal stability, and shear strength, making it ideal for high-performance vehicles or heavy-duty industrial equipment. Although synthetic gear oil is costlier, it lasts longer, delivers better fuel economy, and provides superior protection against wear and corrosion. It also depends on your application, operating conditions, and budget in terms of synthetic versus conventional gear oil.

Synthetic vs. Mineral Gear Oil: What Works for Your Equipment

As far as your equipment and operating conditions are concerned, it is your needs that will determine if you will use synthetic or mineral gear oil. Synthetics gear oils provide superior lubrication, better resistance to extreme temperatures, and longer lasting protection, thus being more indicated for high-performance applications or heavy-duty machinery. They maintain viscosity over a wider temperature range and reduce wear, hence gears and components last longer. Mineral gear oils are cheaper than the synthetic ones, aimed at standard applications, with less demanding conditions. It is lubricated adequately to maintain stable temperatures and loads. While synthetic oil outperforms mineral oil in most respects, mineral oil is good enough for normal applications on most vehicles and equipment. Finally, note temperature, load, and even manufacturer recommendations when choosing the best option for each application.

How Do I Know Which Gear Oil To Use?

First, refer to the user manual for equipment or the manufacturer’s specifications to find out what the appropriate gear oil benefits for an application. Usually, the recommended viscosity grade-for example, 75W-90-and the type of gear oil-synthetic, mineral, or semi-synthetic-are specified. Then, calculate the operating conditions: temperature, load, and environment, as these mean the performance of the lubricant. For example, synthetic gear oils have very high temperature ranges and high-pressure capabilities but are adequately sufficient for ordinary conditions. In addition, observe the existence of EP additives or anti-wear agents which provide an added level of protection in demanding operations. Seeking the advice of a professional mechanic or an expert in lubricants will be very handy in determining the ideal gear oil to provide optimal performance.

Is Gear Oil Essential for Cars?

And a car indeed needs gear oil as this will help ensure that the transmission and differential gear components of the car are duly lubricated, thus allowing these to run both with smoothness and efficiency. It reduces friction and wear on the gears, which helps in elongating the life of these crucial parts, and also provides an effect of cooling whereby the heat generated from the gears in their act of operation is dissipated. Apart from preventing metallic contact that is harmful and costly to repair, gear oil protects against corrosion and rust, especially when you expose your vehicle to high humid conditions or aggressive driving. Always inspect your car’s gear oil and adhere strictly to the manufacturer’s specified time to replace it to keep your car running properly, efficiently, and reliably.

What is Going to Happen If Gear Oil Isn't Changed

Failure to change the gear oil will lead to serious troubles in your automobile’s transmission or differential system. Gear oil gradually loses its lubricating properties because of heat and pressure variables and also, through contamination from metal particles or dirt. As the gear oil loses its friction-reducing qualities, there is an increase in friction between the gears which causes a rise in wear and tear, overheating, and even a possible gear failure. This may thus lead to grinding sounds, failure to shift the gears, or even destruction of the transmission. The forging gear oil does not work effectively, accelerates corrosion and rust, and shortens the life span of gear parts. Gear oil changes should be made regularly to ensure proper performance without raising costly repairs and extending the life of a vehicle’s transmission or differential system.

Gear Oil Change Interval

Ideally, gear oil changes depend on the type of vehicle, how it is used, and the manufacturer’s recommendation. Normally, a standard vehicle should be replaced with a new oil level after travelling 30,000 to 60,000 miles. Heavy-duty trucks, off-road driving and extremely harsh usages or environments may necessitate changes more frequently. Please refer to your owner’s manual for proper maintenance based on your vehicle’s make and model. Periodically checking the gear oil for condition and level is a must. Contamination, discoloration, or unusual noises may mean that it needs gear oil replacement. Maintenance should be followed about gear oil maintenance to ensure smooth operation, optimal performance, and maximized years in your transmission or differential.

Signs That Gear Oil Needs to Be Changed

There are several signs that you should check if it already is time to change your gear oil. If you feel there is grinding, whining, or clunking when shifting gears, this may be a sign of either low lubrication. Some other indications of gear oil contamination include dark, dirty, or gritty color, which should be replaced. Shifting becomes very difficult when jerky motions or slipping transmissions occur, often caused by failure in the effective operation of the gear oil. Burning smells or oil leaks around the area of the transmission or differential also serve as warning signs. Checking on a regular basis the level and condition of gear oil can alert you to develop these problems in time and prevent possible damage in your vehicle’s gears.

Gear Oil vs. Engine Oil: What's the Difference

Gear oil and engine oil are two types of different oil for various purposes and are essentially defined and noted for their distinctions. Gear oil is made to lube gears, transmissions, and other differentials, while engine oil must lube the internal working parts of an engine. Gear oil has a high viscosity, so it can operate at the higher pressure and loading seen in gear systems. Also, it contains EP additives, which provide added protection. In comparison, engine oil is developed to perform better over a broader temperature range and remain resistant to oxidation while keeping the engine clean by avoiding sludge buildup. Again, these two oils were not designed to be used interchangeably; their properties are engineered to meet specific needs for their intended applications.

Gear Oil vs. Engine Oil: Viscosity Comparison

Gear oil and engine oil do not have the same viscosity. This would also explain why gear oils are usually thicker and may offer greater protective film between two metal surfaces in a high-pressure gear system. Such high viscosity is critical in preventing wear and tear between transmission and differentials. Compared to this, engine oils have thinner viscosity grades so that it could flow better through the narrow passages of the engine. The viscosity of gear oils is rated in SAE ratings such as 75W-90, whereas engine oils are rated by grade ratings such as 10W-30. This type of rating ensures the proper oil is chosen for any given system’s specific operating conditions.