What is Gear Oil and Where Does it Get Used?

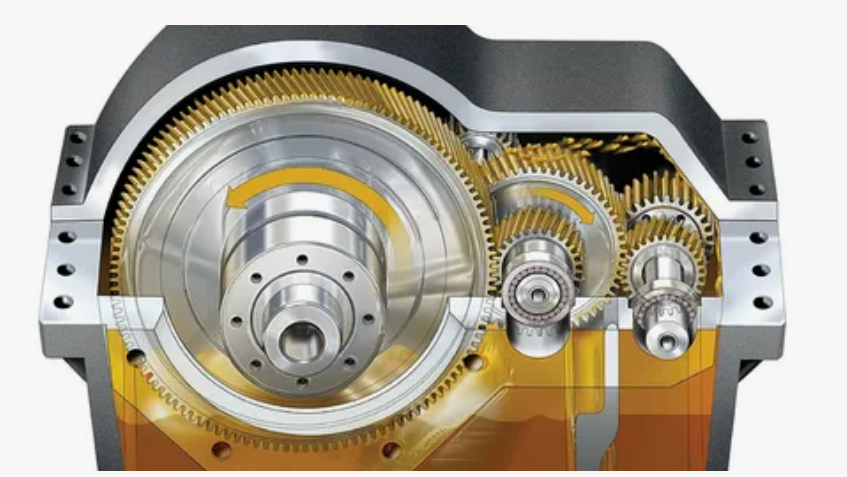

Gear oil is a specially formulated lubricant designed for high-pressure applications in gears, such as those in automotive transmissions, differentials, and industrial machinery. Its primary function is to reduce friction, prevent wear, and protect the components from heat and corrosion. Gears require oils that can endure extreme pressure and maintain lubrication despite high loads. You’ll find gear oil commonly used in vehicles, heavy equipment, agricultural machinery, and industrial gear systems where a standard oil wouldn’t withstand the pressure and stress.

Gear Oil Grades and Numbers Explained

Gear oil is classified by the Society of Automotive Engineers (SAE) with specific grades based on viscosity. Common SAE grades include 75W-90, 80W-90, and 85W-140. The “W” stands for “Winter” and indicates the oil’s performance at low temperatures. For example, 75W-90 is formulated to flow more easily at lower temperatures compared to 85W-140. Higher viscosity numbers indicate a thicker oil, which is often more suitable for high-load applications. Choosing the correct grade based on the operating environment is essential to maintain optimal performance and prevent gear wear.

There Are Different Types of Gear Oil

There are various types of gear oils, each suited to specific applications. Here are the most common:

- GL-4: Primarily used in manual transmissions and transaxles.

- GL-5: Formulated for hypoid gears and differential applications with extreme pressure additives to prevent wear.

- Hypoid Gear Oil: A type of GL-5 gear oil designed for hypoid gears, which have a unique shape and operate under higher pressures.

Different vehicles and equipment require specific types, so referring to the owner’s manual or manufacturer’s recommendations is essential for proper application.

Is Gear Oil Important for Cars?

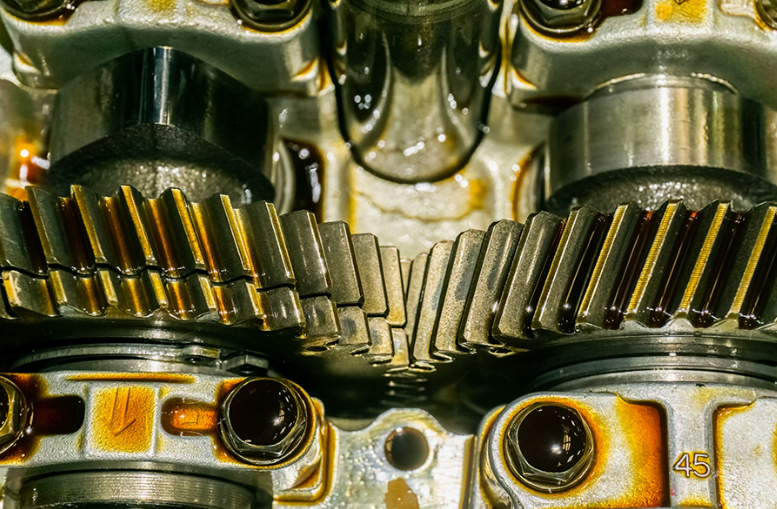

Yes, gear oil is critical for the smooth operation and longevity of a car’s transmission and differential. It ensures that gears mesh smoothly, reducing noise, wear, and tear, especially under high-torque conditions. Over time, gear oil can break down and lose its effectiveness, leading to increased wear, reduced efficiency, and potential component failure. Proper gear oil maintenance is key to preventing costly repairs.

The Problems with Bad/Old Gear Oil

Old or contaminated gear oil can lead to several issues, including:

- Increased Friction: Leads to overheating and reduced efficiency.

- Gear Wear: Depleted additives and degraded oil fail to provide proper lubrication.

- Rust and Corrosion: Condensation and contaminants can cause corrosion within the gear assembly.

Regularly checking and replacing gear oil helps avoid these issues, extending the life of the vehicle’s drivetrain components.

Gear Oil vs. Engine Oil: What’s the Difference?

Gear oil and engine oil serve distinct purposes and are chemically different. Gear oil is thicker and designed to withstand high pressures without breaking down, thanks to extreme pressure (EP) additives. Engine oil, on the other hand, is thinner and designed primarily to lubricate, cool, and clean engine components, with detergents and dispersants. Gear oil’s higher viscosity allows it to cling to gears under pressure, unlike engine oil, which is suited for high-speed, low-pressure applications within engines.

Engine Oil Viscosity Grades Explained

Engine oil is also graded by SAE standards (e.g., 5W-30, 10W-40), but these focus on flow characteristics rather than pressure resistance. Lower numbers indicate easier flow in cold conditions, while higher numbers show greater thickness in warm temperatures. Understanding engine oil viscosity is helpful for comparison with gear oil, as engines and transmissions operate under different conditions and need tailored lubrication.

Synthetic vs. Conventional Gear Oil

Synthetic gear oils offer enhanced performance over conventional oils, especially in extreme temperatures. They have higher resistance to oxidation, better stability at high temperatures, and superior flow characteristics at low temperatures. Conventional oils, however, are less expensive and may be suitable for standard operating conditions. Many manufacturers recommend synthetic oils for heavy-duty or high-performance vehicles due to their longevity and protective benefits.

Viscosity is Important

The viscosity of gear oil is crucial because it impacts the lubricant’s ability to cling to gears, reducing friction and wear. If the oil is too thin, it may not provide adequate protection, especially under high loads. Too thick, and it can cause increased drag, reducing efficiency. The right viscosity allows for optimal performance, balancing lubrication with the necessary flow.

Gear Oil vs. Engine Oil: Viscosity Comparison

Gear oil typically has a higher viscosity than engine oil, ensuring that it can provide the necessary lubrication under high pressure. For example, 75W-90 gear oil is thicker than 10W-30 engine oil. The viscosity difference is important because gear mechanisms require oils that can withstand shearing forces without breaking down, unlike engines where high-speed moving parts need a lighter, easily circulated oil.

Gear Oil Undergoes Boundary Lubrication

Boundary lubrication occurs when the lubricating film between surfaces is minimal. Gear oil, with its high viscosity and additives, supports boundary lubrication by providing a film that minimizes direct metal-to-metal contact under high-pressure scenarios. This type of lubrication is essential for gears, especially hypoid gears, which experience significant pressure and sliding forces.

Gear Oil vs. Engine Oil: Additional Differences

Additional differences include additive packages. Gear oils contain extreme pressure (EP) additives like sulfur-phosphorus compounds to protect against wear, which are not present in engine oils. Additionally, gear oils must endure higher loads and have anti-foam agents to prevent foaming that can reduce lubrication efficiency.

Typical Drivetrain Fluid Additives

Common additives in gear oil include:

- Anti-Wear Agents: Reduce gear wear by providing a protective layer.

- Extreme Pressure Additives: Protect against heavy loads and prevent scoring and pitting.

- Oxidation Inhibitors: Help prevent oil breakdown from heat.

- Anti-Foaming Agents: Prevent bubbles that can reduce lubrication.

These additives ensure that gear oil can meet the high demands of drivetrain systems.

Common Gear Designs

Different gear designs include spur, helical, bevel, and hypoid gears. Each type operates under distinct mechanical conditions. For instance, hypoid gears in differentials need gear oil that can withstand high pressures and sliding motion. Understanding the gear design helps in selecting the appropriate oil type, ensuring that it meets specific mechanical demands.

When to Change Gear Oil

Gear oil typically needs replacement every 30,000 to 50,000 miles, depending on the manufacturer’s guidelines. Some indicators that it’s time to change include unusual noises from the drivetrain, oil discoloration, and reduced gear smoothness. Following a regular change schedule ensures optimal gear performance and prevents long-term damage.

How to Choose the Right Lubricant for Your Gear?

hoosing the right gear oil involves:

- Checking the owner’s manual for recommendations.

- Considering the environment and operating conditions (temperature, load).

- Selecting the appropriate grade based on SAE standards.

- Determining if synthetic oil is preferable for extreme conditions or high-performance applications.

Choosing the correct lubricant can improve efficiency and extend gear life, so always prioritize the specific needs of the equipment.

Final Thoughts

Gear oil plays an essential role in the performance and longevity of automotive and industrial gear systems. By understanding the types, grades, and applications of gear oil, users can make informed choices that enhance durability and reduce maintenance costs. Regular gear oil maintenance prevents wear, optimizes efficiency, and ensures that vehicles and machinery run smoothly under various conditions.

FAQs

Gear oil is specifically formulated to lubricate gear systems under high-pressure conditions, such as in differentials and manual transmissions, while transmission fluid (especially automatic transmission fluid, or ATF) is tailored to handle the hydraulic and friction requirements of automatic transmissions. Transmission fluid also has added friction modifiers and sometimes detergents, unlike gear oil.

No, motor oil is not designed to withstand the extreme pressures present in gears. Gear oil has unique additives to handle high shear forces and is usually thicker. Using motor oil can lead to inadequate lubrication, increased wear, and potential gear failure.

Signs that gear oil may need replacing include noisy gears, difficulty shifting (in manual transmissions), oil discoloration (dark or gritty oil), and a burning smell from the drivetrain area. Regular inspections help catch these signs early.

While it’s technically possible, mixing synthetic and conventional gear oil is generally not recommended as it can compromise performance and might not provide optimal protection. It’s best to stick with one type and follow the manufacturer’s guidelines.

Using the wrong grade of gear oil can lead to issues like inadequate lubrication, increased friction, and potential gear wear. High-viscosity oil might cause drag, while low-viscosity oil may fail to provide sufficient protection under load. Always choose the grade recommended for your specific gear system.